Technology

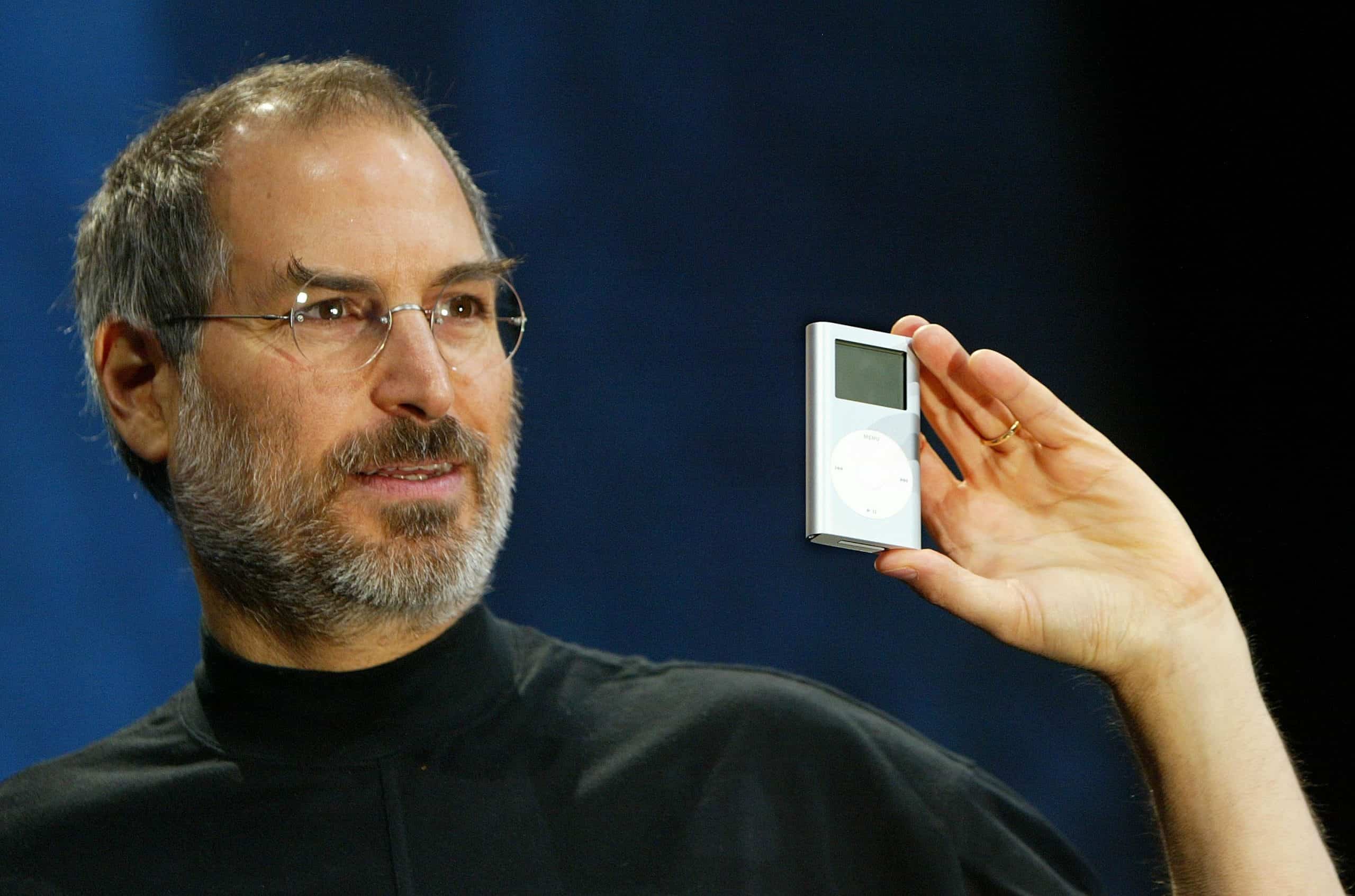

Do You Know Where Your iPhone Came From? This Is What It Takes to Put Technology in Your Pocket

Published:

It’s no secret that massive amounts of human suffering and even death go into the creation of the iPhone, but where exactly do the materials come from, and what is the cause of the suffering? Where did the little phone we use actually come from?

Apple (NASDAQ:AAPL) sources its components from 43 countries with most of the assembly taking place in Taiwanese facilities owned by Foxconn, Pegatron, Compal Electronics, and Wistron. Most of these factories are located in China with new additions in Brazil and India.

Apple doesn’t own any of the mines, factories, or other facilities that are necessary for iPhones to exist. Instead, companies extract the materials themselves and then create the microchips according to Apple’s specifications. Apple then purchases the components and sends them to China to be assembled.

Apple does this for a number of reasons, the most important being: it’s cheaper. In the countries where these minerals are mined, corruption runs rampant, people are poor and starving, and labor laws are much more flexible or nonexistent. The companies that extract these minerals are able to exploit their workers and charge much less than a mine in America would.

Additionally, Apple has deniability when it comes to the human rights abuses that occur in these locations because it doesn’t own them. However, its relationship with these companies and mines has come under criticism in recent years.

Apple’s manufacturer contractors, Foxconn and Inventec, located in China, have both faced numerous accusations of running sweatshops.

In 2020, the Australian Strategic Policy Institute announced that Apple was “potentially directly or indirectly benefitting from forced Uyghur labor” in China. That same year, Apple’s lobbyists tried to kill the Uyghur Forced Labor Prevention Act in U.S. Congress.

Gold is used for making pins on microchips, relays, cameras, connectors, charging coils, and as a core part of logic boards. Most of the gold in your iPhone was mined in Mongolia, South America, and Africa.

The copper in your iPhone, which is primarily used for wires and other conductive components, was probably mined in Chile.

Tantalum is used to make anodes. These are critical parts of smartphone capacitors that store the electrical charge for the iPhone to access and use during operation. Most of the tantalum in your iPhone came from mines in the Democratic Republic of the Congo.

The DRC is rife with corruption and the wealth gap is extreme, forcing poor and starving families to work in the mines that source tantalum for Apple. These mines require back-breaking hard work, intensive labor, and long hours, while the workers barely get paid enough to survive for a day.

Apple uses sapphire crystal to create its lens covers for the iPhone cameras. They are more resistant to scratching than other types of crystal or glass, but more prone to cracking in general.

There are many more resources that go into making all the components in the iPhone, and thousands of steps from the Earth to the final assembly line. You can find Aluminum, Silver, Chrome, and other valuable minerals in your phone.

For example, one mine in Bolivia is used to source tin, lead, zinc, and silver. Some of the minerals from this mine are used to create iPhones, but the mind has been worked for so long and exploited so heavily that experts say the whole mountain might collapse. But 15,000 locals are still forced to work in the mine, including children as young as six.

The processors that run your iPhone are made in Taiwan, which is where most of the microchips in the world are made.

The iPhone’s display is usually made in South Korea by either LG or Samsung. The DRAM and flash memory components are made in Japan. The screen protectors are made in Japan, Taiwan, and in the USA. The semiconductors that power the phones are made in Taiwan.

After all the materials have been sourced and the different parts created, they are all sent to Foxconn locations around the world to be assembled. Most of the phones are assembled in China.

In one factory, it was reported that over 200,000 workers lived and worked in the facility and were forced to work more than 60 hours every week. They were only paid $100 per month and were required to live in the factory, buy their food from the factory, and pay rent to the factory. They were given buckets to do their laundry. In Pegatron’s facilities, workers are not paid enough to cover their living expenses, so they are forced to work excessive amounts of overtime in order to survive.

In 2010, some workers in China were poisoned by the cleaner they used to clean the LCD screens on iPhones.

In 2014, BBC discovered that labor violations had continued in recent years after the now-famous string of suicides at Foxconn facilities in 2010.

After assembly, iPhones are shipped to a location in Ireland where they are tested to see if manufacturing has been done according to Apple’s standards and can be shipped and sold around the world.

Apple chooses to ship its iPhones by air (instead of by ship), leading to higher prices but shorter order and wait times. The fast development and release of each iPhone model means Apple is highly incentivized to shorten the time from manufacture to sale.

Thank you for reading! Have some feedback for us?

Contact the 24/7 Wall St. editorial team.